The scope of application of metal and plastic is expanding every year. Today, it is impossible to imagine life without these two materials.

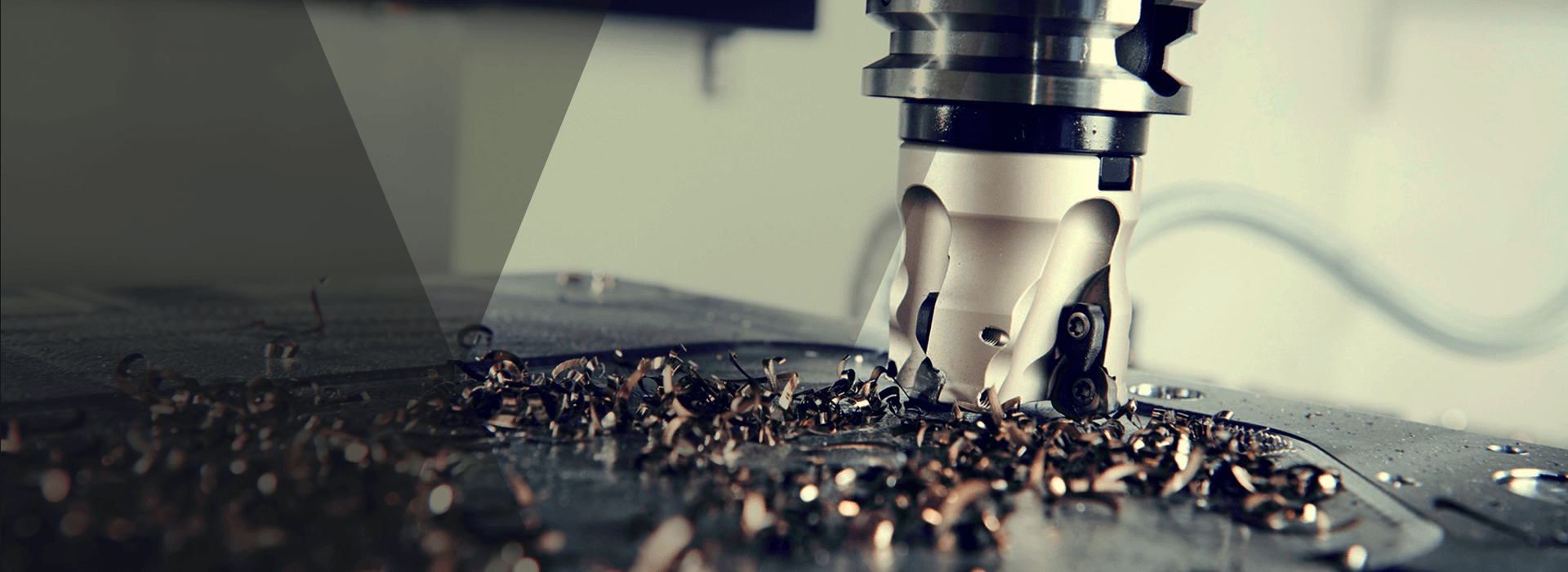

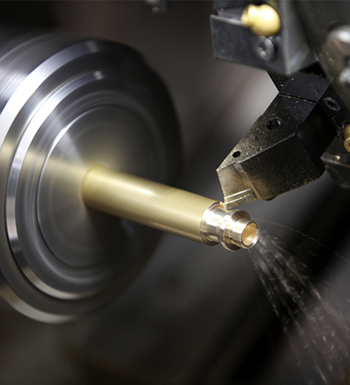

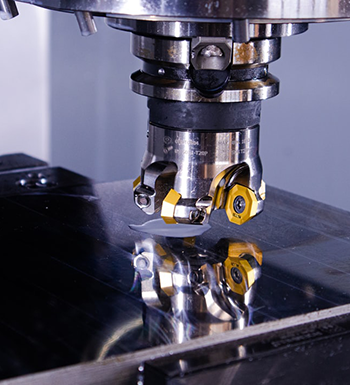

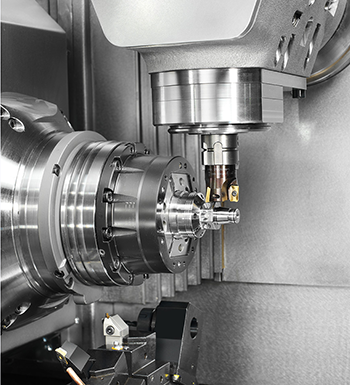

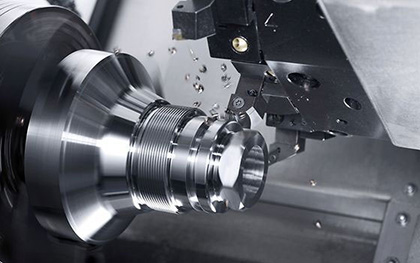

But to produce metal and plastic products that are high-quality and standardized, special skills, a team of professionals, and appropriate equipment are required!

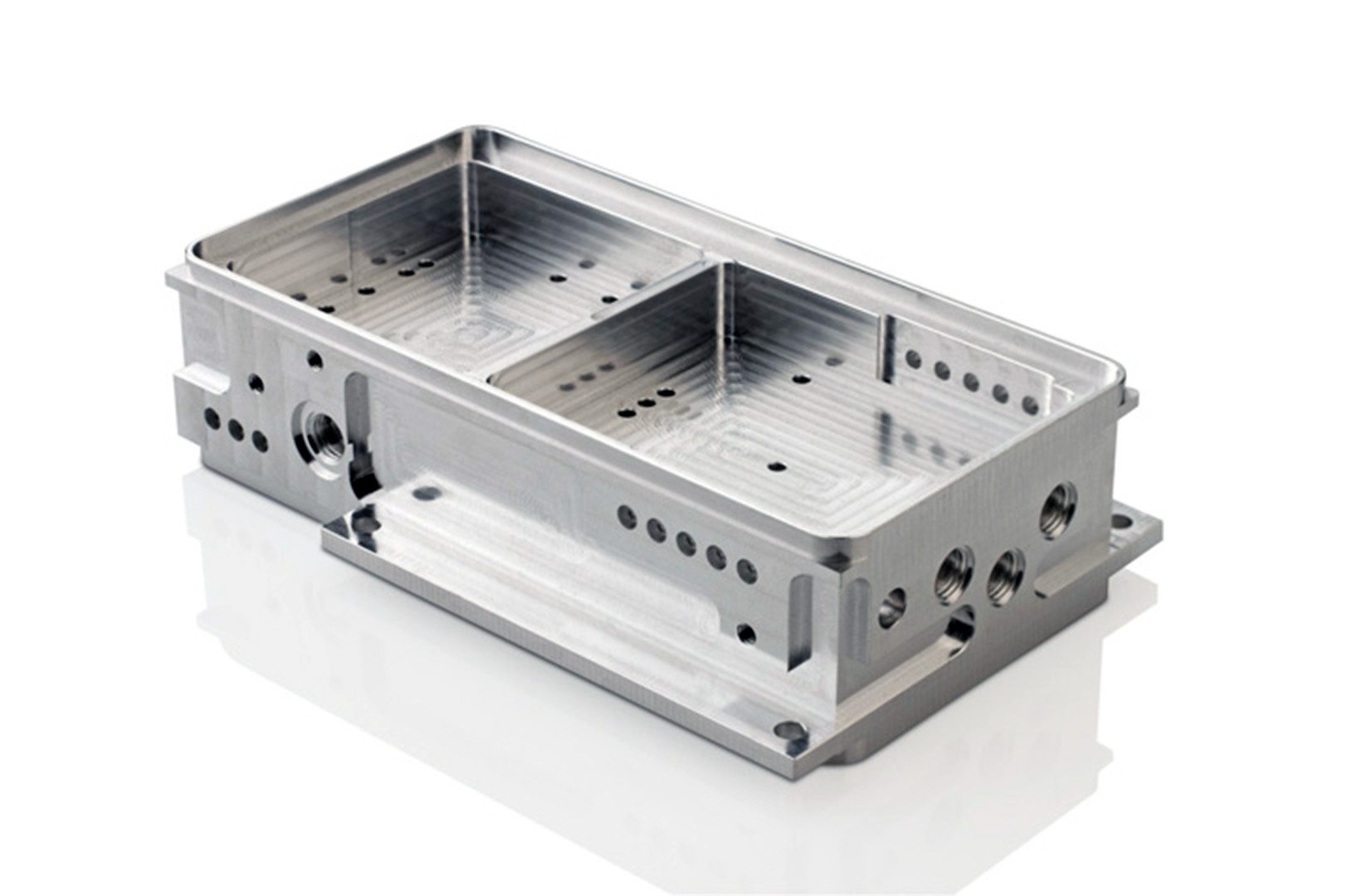

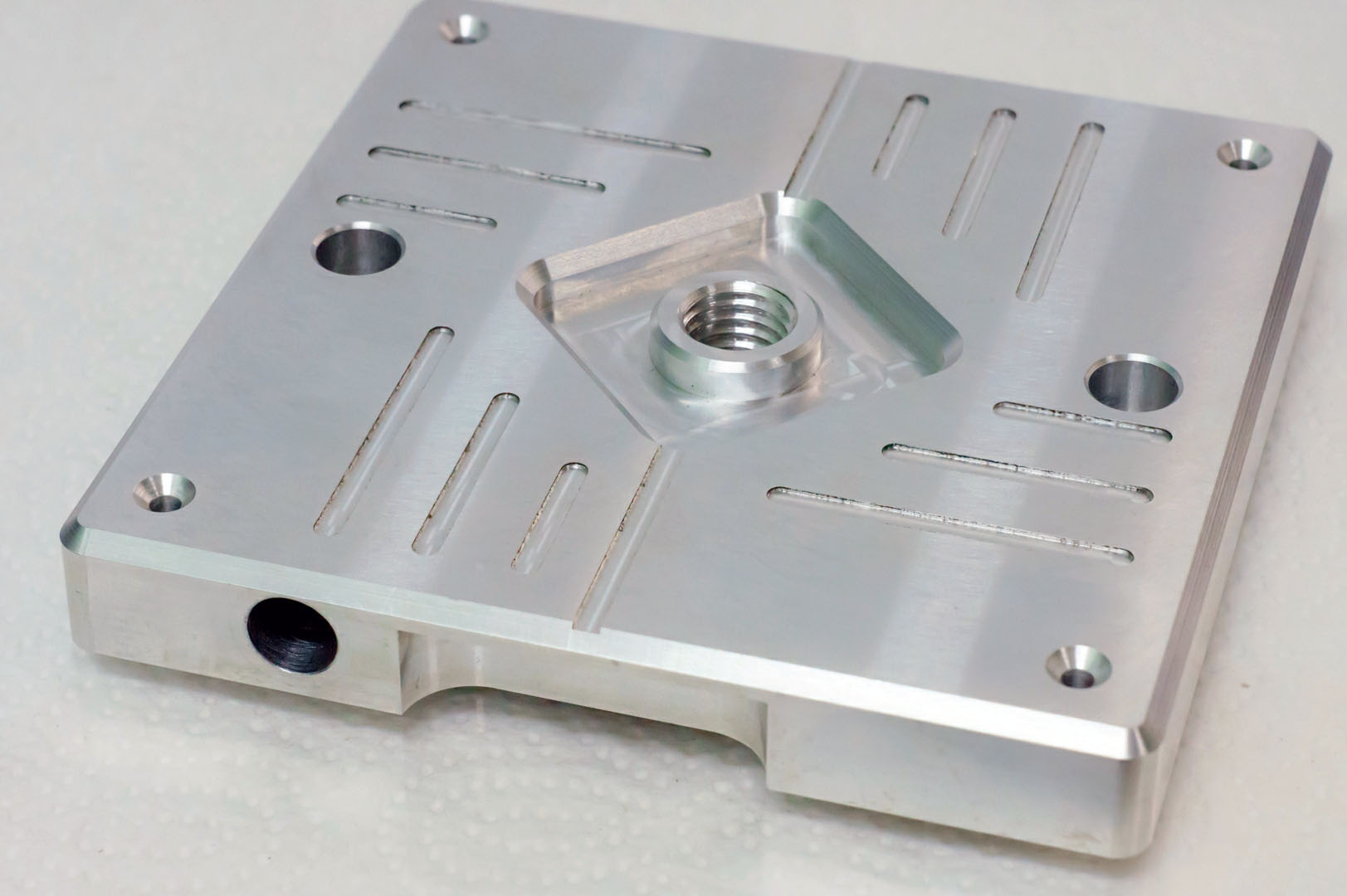

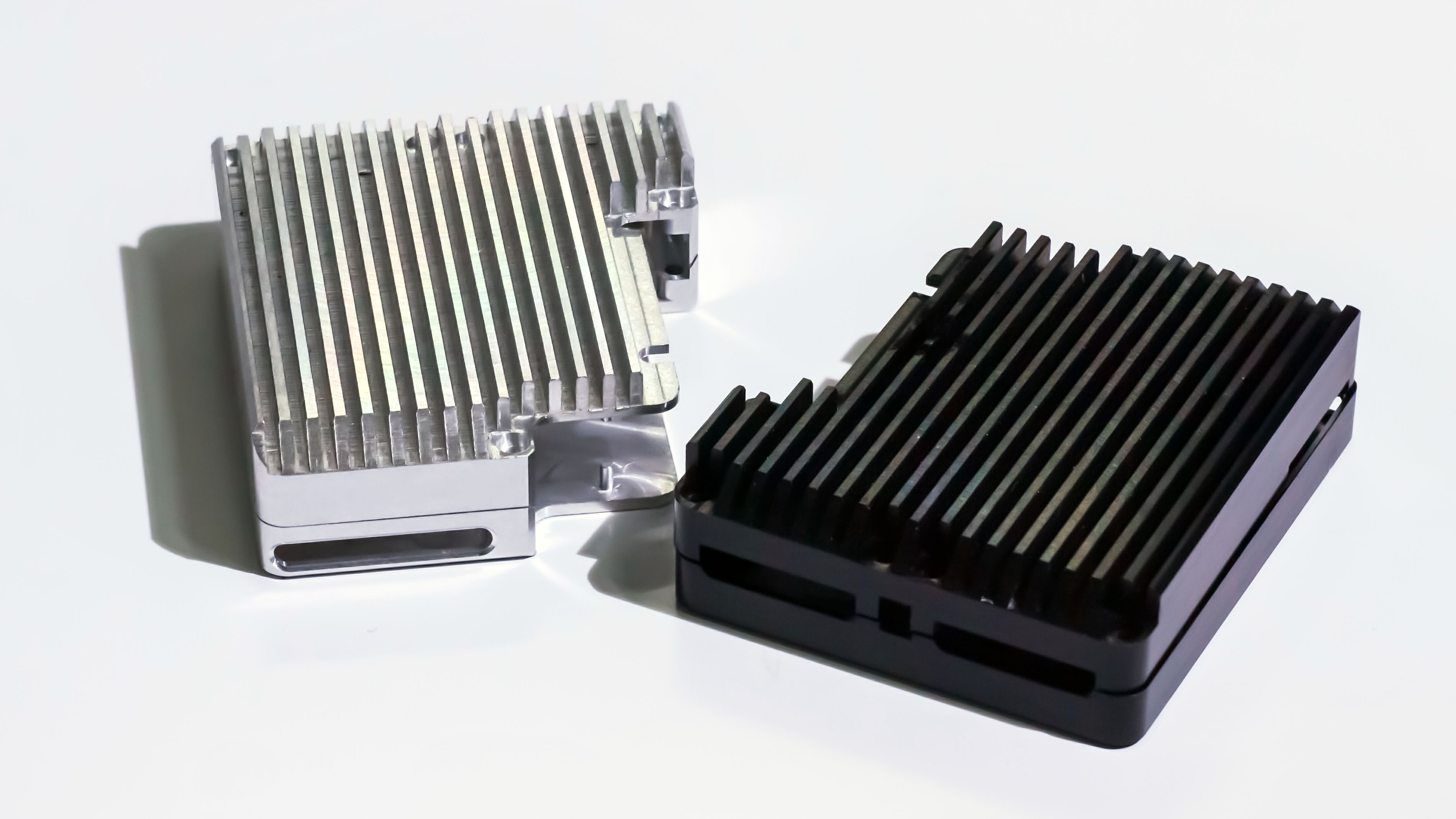

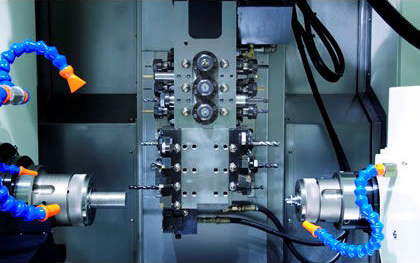

We manufacture enclosure products from aluminum and plastic. With attention to detail, we have been working for the past five years. Using the latest technologies and modern equipment, we provide solutions even for the most complex production tasks!

Continuous improvement is our motto. We do not stand still; we develop and grow!

Learn More

Fanerna, 4, Kyiv, 02160

Fanerna, 4, Kyiv, 02160 (097) 453-72-53

(097) 453-72-53 cnc@alial.com.ua

cnc@alial.com.ua